0086 15335008985

Ciri teknikal

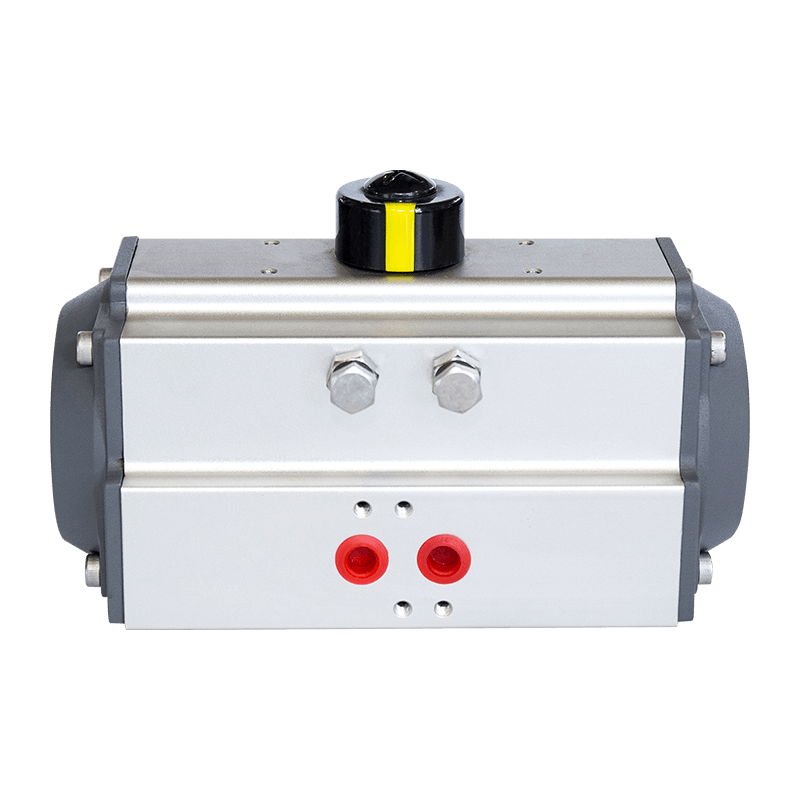

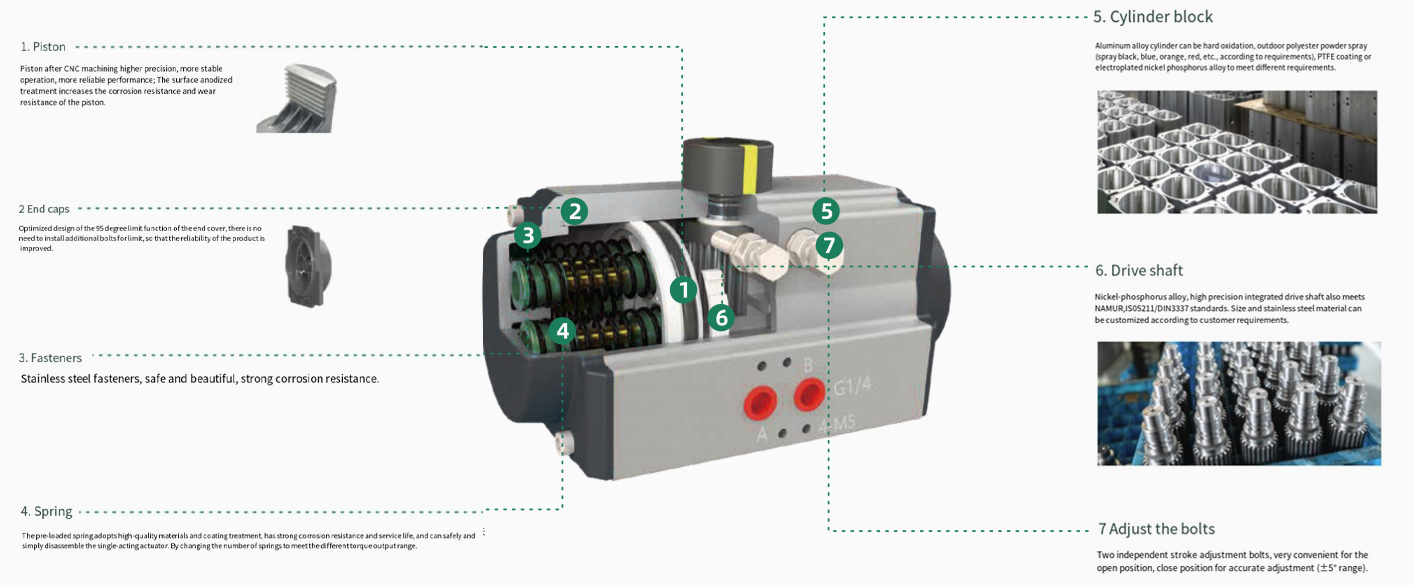

Pada penggerak pneumatik siri menggunakan peralatan pemesinan ketepatan lanjutan, bahan berkualiti tinggi, dan teknologi reka bentuk seni perindustrian. Selepas ujian yang ketat dan pengoptimuman barisan pengeluaran, siri penggerak ini mempunyai kelebihan operasi yang lancar dan boleh dipercayai, kehidupan kerja yang panjang, pelbagai laras yang besar, prestasi anti karat yang tinggi, pemilihan fleksibel, dan keberkesanan kos.

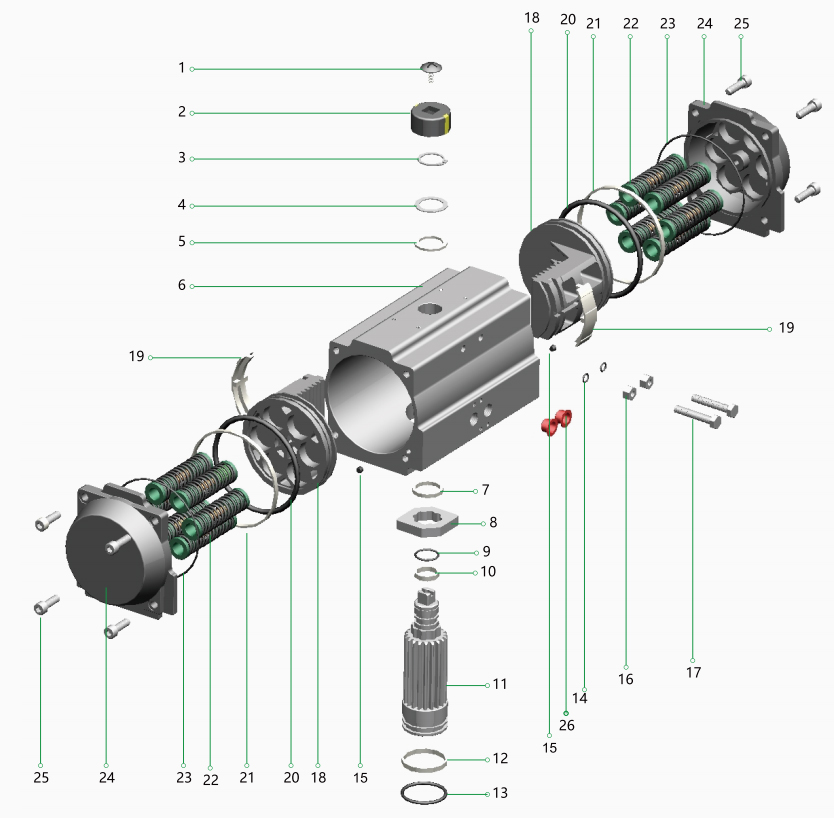

Bahagian dan bahan

| Nombor | Nama | Qty | Bahan | Anticorrosion | Pilihan |

| 1 | Skru penunjuk | 1 | Plastik Kejuruteraan Keluli Stainless | ||

| 2 | Penunjuk | 1 | Plastik Kejuruteraan | ||

| 3 | CIRCLIP | 1 | Keluli tahan karat | ||

| 4 | mesin basuh | 1 | Keluli tahan karat | ||

| 5 | Gasket luaran | 1 | Plastik Kejuruteraan | ||

| 6 | Silinder | 1 | Profil Aluminium (6005-T5) | Anodizing keras, dll. | |

| 7 | Gasket dalaman | 1 | Plastik Kejuruteraan | ||

| 8 | Cam | 1 | 45 # keluli | ||

| 9 | Aci atas o-ring | 1 | Getah nitril | Fluororubber/Getah Nitril Suhu Rendah | |

| 10 | Cincin sokongan aci atas | 1 | Plastik Kejuruteraan | ||

| 11 | Aci pemacu | 1 | keluli aloi | Fosforus nikel | Keluli tahan karat |

| 12 | Cincin sokongan aci yang lebih rendah | 1 | Plastik Kejuruteraan | ||

| 13 | Aci bawah O-ring | 1 | Getah nitril | Fluororubber/Getah Nitril Suhu Rendah | |

| 14 | Menyesuaikan bolt o-ring | 2 | Getah nitril | Fluororubber/Getah Nitril Suhu Rendah | |

| 15 | Palam | 2 | Getah nitril | ||

| 16 | Kacang | 2 | Keluli tahan karat | ||

| 17 | Menyesuaikan bolt | 2 | Keluli tahan karat | ||

| 18 | omboh | 2 | Cast aluminium | Pengoksidaan | |

| 19 | Panduan Piston | 2 | Plastik Kejuruteraan | ||

| 20 | Piston O-ring | 2 | Getah nitril | Fluororubber/Getah Nitril Suhu Rendah | |

| 21 | Cincin sokongan omboh | 2 | Plastik Kejuruteraan | ||

| 22 | Spring | 0 ~ 12 | Keluli musim bunga | Cat elektroforetik | |

| 23 | Akhir cap o-ring | 2 | Getah nitril | Fluororubber/Getah Nitril Suhu Rendah | |

| 24 | Topi akhir | 2 | Cast aluminium | Salutan serbuk, dll. | |

| 25 | Skru penutup akhir | 8 | Keluli tahan karat | ||

| 26 | Palam habuk | 2 | plastik |

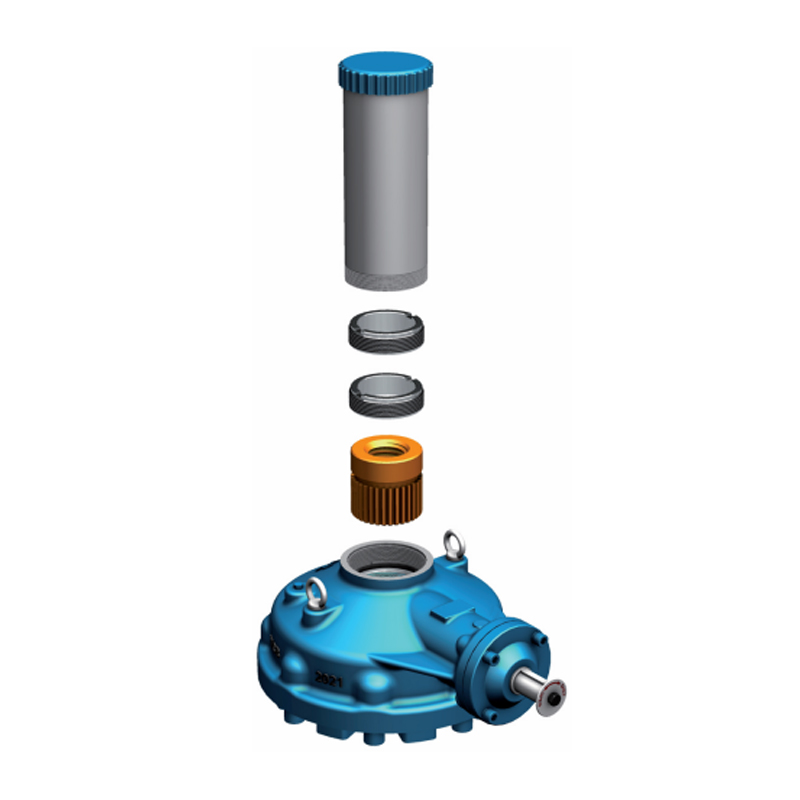

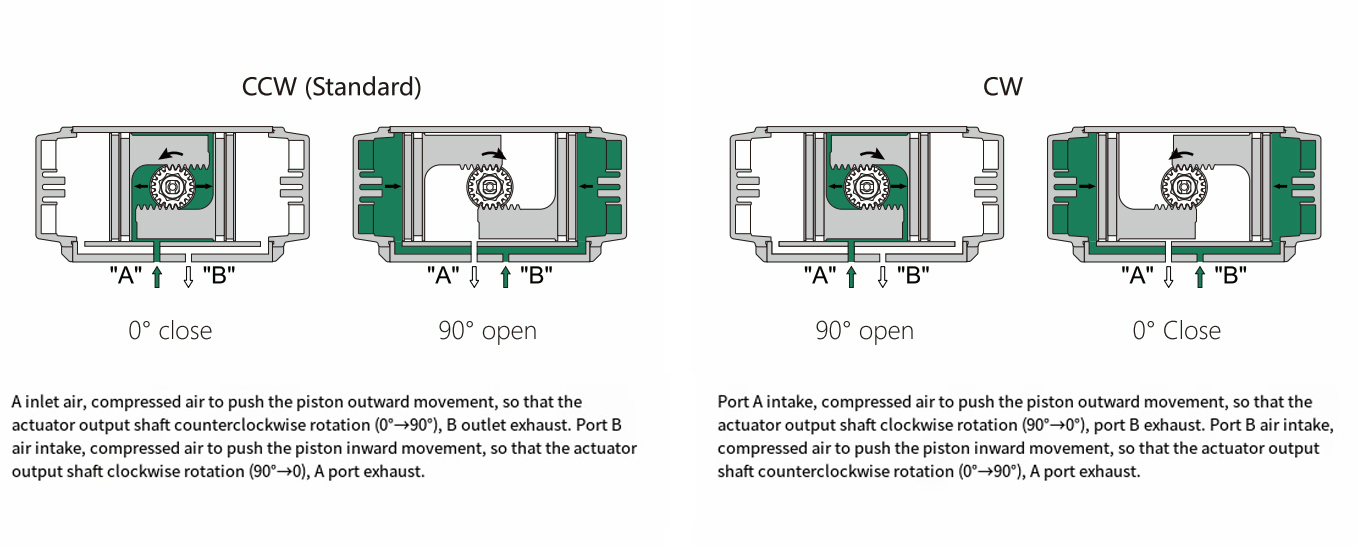

Prinsip kerja

Penggerak penggerak berganda

Penggerak lakonan tunggal

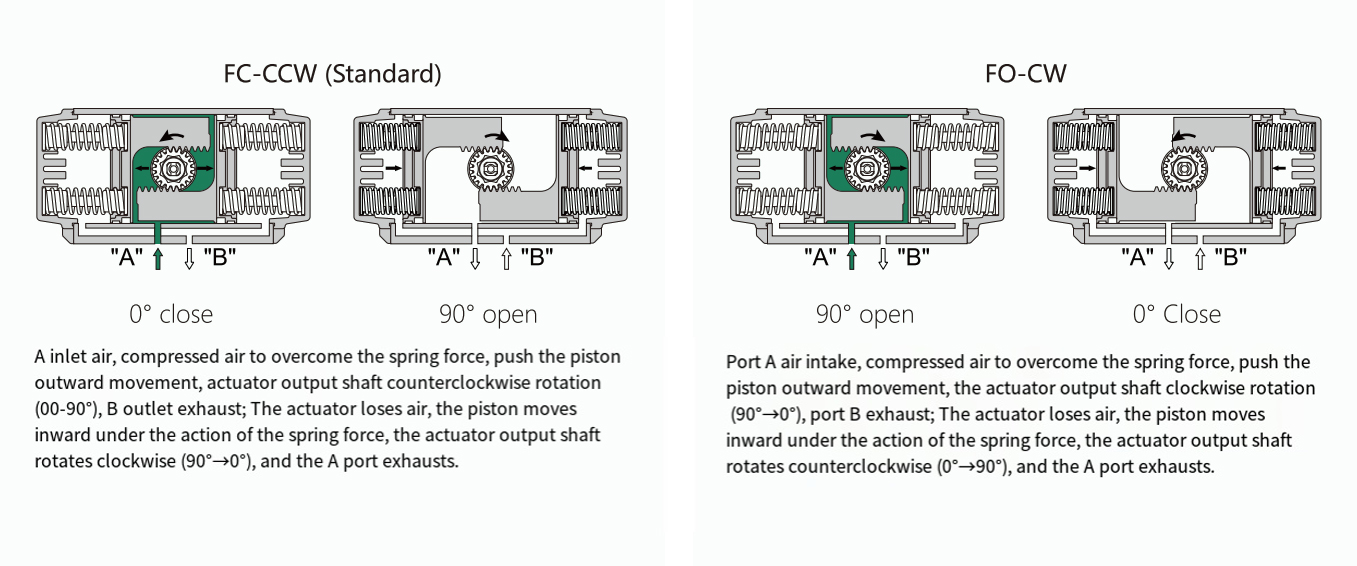

Tork output bertindak berganda

| Model | Tekanan Bekalan Udara (Unit: Bar) | |||||||||

| 2 | 2.5 | 3 | 4 | 4.5 | 5 | 5.5 | 6 | 7 | 8 | |

| DA-32 | 3 | 4 | 5 | 6 | 7 | 8 | 8 | 9 | 11 | 12 |

| DA-40 | 5 | 6 | 7 | 10 | 11 | 12 | 13 | 14 | 17 | 19 |

| DA-52 | 8 | 10 | 12 | 16 | 18 | 20 | 22 | 24 | 28 | 32 |

| DA-63 | 15 | 18 | 22 | 29 | 33 | 36 | 40 | 44 | 51 | 58 |

| DA-75 | 20 | 25 | 30 | 40 | 45 | 50 | 55 | 60 | 70 | 80 |

| DA-83 | 31 | 39 | 47 | 63 | 70 | 78 | 86 | 94 | 110 | 125 |

| DA-92 | 45 | 56 | 68 | 90 | 102 | 113 | 124 | 135 | 158 | 181 |

| DA-105 | 66 | 83 | 99 | 132 | 149 | 165 | 182 | 198 | 231 | 264 |

| DA-125 | 100 | 125 | 150 | 200 | 226 | 251 | 276 | 301 | 351 | 401 |

| DA-140 | 171 | 214 | 256 | 342 | 385 | 427 | 470 | 513 | 598 | 684 |

| DA-160 | 266 | 332 | 399 | 532 | 598 | 665 | 731 | 798 | 931 | 1064 |

| DA-190 | 426 | 532 | 638 | 851 | 958 | 1064 | 1170 | 1277 | 1490 | 7702 |

| DA-210 | 532 | 665 | 798 | 1064 | 1197 | 1330 | 1463 | 1596 | 1862 | 2128 |

| DA-240 | 769 | 962 | 1154 | 1539 | 1731 | 1924 | 2116 | 2308 | 2693 | 3078 |

| DA-270 | 1170 | 1462 | 1754 | 2339 | 2632 | 2924 | 3216 | 3509 | 4094 | 4679 |

| DA-300 | 1526 | 1908 | 2289 | 3052 | 3434 | 3815 | 4197 | 4578 | 5341 | 6104 |

| DA-350 | 2285 | 2856 | 3427 | 4570 | 5141 | 5712 | 6283 | 6854 | 7997 | 9139 |

| DA-400 | 3256 | 4070 | 4884 | 6512 | 7326 | 8140 | 8954 | 9768 | 11396 | 13024 |

Pemilihan penggerak berganda:

Di bawah keadaan operasi biasa, faktor keselamatan penggerak bertindak dua adalah 20%-30%.

Contoh:

Tork injap = 100nm

Tork keselamatan = 100x (1 30%) = 130nm

Tekanan sumber udara = 5bar

Menurut jadual tork bertindak dua, spesifikasi minimum penggerak bertindak dua adalah ADA105.

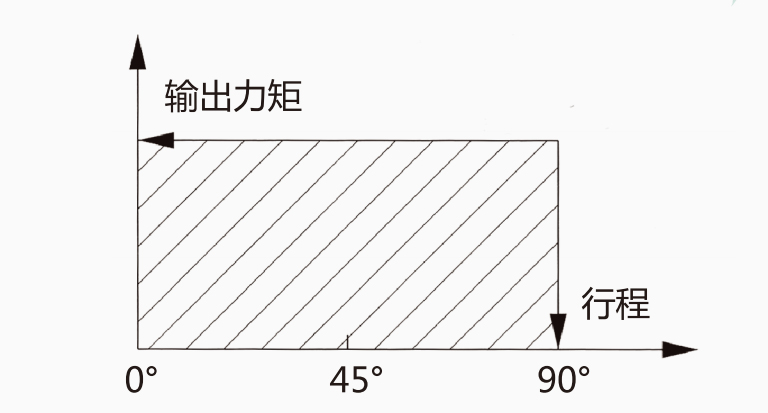

Tork output bertindak tunggal

| Tork output | Springs'output | ||||||||||||||||

| Tekanan udara | 2.5bar | 3BAF | 4BAR | 5bar | 6bar | 7BAR | 8BAR | ||||||||||

| Model | Spring Qty | 0 ° | 90 | 0 ° | 90 | 0 ° | 90 | 0 ° | 90 ° | 0 ° | 90 ° | 0 ° | 90 ° | 0 ° | 90 ° | 90 ° | 0 ° |

| Mula | Akhir | Mula | Akhir | Mula | Akhir | Mula | Akhir | Mula | Akhir | Mula | Akhir | Mula | Akhir | Mula | Akhir | ||

| ASR-40 | K2 | 1.3 | 2.7 | 5.0 | 1.4 | 75 | 3.1 | 9.8 | 4.5 | 7.5 | 4.8 | ||||||

| ASR-52 | K5 | 5.7 | 3.8 | 7.6 | 5.7 | 6.2 | 4.3 | ||||||||||

| K6 | 4.9 | 2.5 | 6.9 | 4.5 | 10.9 | 8.5 | 7.4 | 5 | |||||||||

| K7 | 4.0 | 1.3 | 6.0 | 3.3 | 9.8 | 7.3 | 14.0 | 10.4 | 8.6 | 5.9 | |||||||

| K8 | 5.2 | 2.0 | 9.2 | 6.0 | 13.2 | 9.1 | 17.2 | 14.1 | 9.9 | 6.7 | |||||||

| K9 | 4.3 | 0.8 | 8.3 | 4.8 | 12.3 | 7.9 | 16.3 | 12.8 | 20.3 | 16.8 | 11.1 | 7.6 | |||||

| K10 | 7.4 | 3.6 | 11.5 | 6.7 | 15.5 | 11.6 | 19.5 | 15.6 | 12.4 | 8.5 | |||||||

| 11 | 6.6 | 2.3 | 10.6 | 5.4 | 14.6 | 10.4 | 18.6 | 14.3 | 22.6 | 18.3 | 13.6 | 93 | |||||

| K12 | 9.7 | 4.2 | 13.8 | 9.1 | 17.8 | 12.2 | 21.8 | 17.1 | 14.8 | 10.2 | |||||||

| ASR-63 | K5 | 11.4 | 7.7 | 15.0 | 11.4 | 22.3 | 18.9 | 10.4 | 6.8 | ||||||||

| K6 | 10.1 | 5.7 | 13.6 | 9.3 | 20.9 | 16.6 | 28.3 | 23.9 | 12.5 | 8.2 | |||||||

| K7 | 8.6 | 3.6 | 12.5 | 7.2 | 19.5 | 14.5 | 26.8 | 21.9 | 14.6 | 9.6 | |||||||

| K8 | 10.9 | 5.1 | 18.2 | 12.4 | 25.5 | 19.8 | 32.8 | 27.0 | 40.1 | 34.3 | 16.7 | 10.9 | |||||

| K9 | 16.8 | 10.4 | 24.1 | 17.7 | 31.4 | 24.9 | 38.7 | 32.2 | 18.8 | 12.3 | |||||||

| K10 | 14 | 8.2 | 22.8 | 15.6 | 30.0 | 22.8 | 37.3 | 30.1 | 44.7 | 37.4 | 20.9 | 13.7 | |||||

| k11 | 21.5 | 13.5 | 28.7 | 20.7 | 36.0 | 28.0 | 43.3 | 35.3 | 22.9 | 15.0 | |||||||

| K12 | 20.0 | 11.4 | 27.3 | 18.6 | 34.6 | 25.9 | 41.9 | 33.3 | 25.0 | 16.4 | |||||||

| ASR-75 | K5 | 14.5 | 10.6 | 19.4 | 15.5 | 29.5 | 25.7 | 14.5 | 10.5 | ||||||||

| K6 | 12.4 | 7.6 | 17.3 | 12.6 | 27.4 | 22.7 | 37.5 | 32.8 | 17.4 | 12.7 | |||||||

| K7 | 10.4 | 4.8 | 15.2 | 9.7 | 25.3 | 19.9 | 35.4 | 29.9 | 20.3 | 14.8 | |||||||

| K8 | 13.1 | 6.8 | 23.1 | 16.9 | 33.3 | 27.0 | 43.2 | 37.0 | 53.3 | 47.0 | 23.2 | 16.9 | |||||

| K9 | 21.0 | 14.1 | 31.2 | 24.1 | 41.1 | 34.1 | 51.2 | 44.2 | 26.1 | 19.0 | |||||||

| k10 | 19.0 | 11.1 | 28.8 | 21.2 | 39.0 | 31.2 | 49.1 | 41.2 | 59.1 | 51.2 | 29.0 | 21.1 | |||||

| K11 | 27.0 | 18.3 | 37.0 | 28.3 | 47.0 | 38.4 | 57.0 | 48.4 | 31.9 | 23.2 | |||||||

| K12 | 24.9 | 15.4 | 34.9 | 25.4 | 44.9 | 35.4 | 54.9 | 45.4 | 34.7 | 25.3 | |||||||

| ASR-140 | K5 | 128 | 85 | 171 | 127 | 256 | 213 | 129 | 86 | ||||||||

| K6 | 111 | 59 | 154 | 102 | 239 | 187 | 325 | 273 | 155 | 103 | |||||||

| K7 | 94 | 33 | 137 | 76 | 222 | 162 | 308 | 247 | 181 | 120 | |||||||

| K8 | 120 | 50 | 205 | 136 | 291 | 221 | 376 | 307 | 462 | 392 | 206 | 137 | |||||

| K9 | 187 | 110 | 273 | 196 | 358 | 281 | 444 | 367 | 232 | 155 | |||||||

| K10 | 170 | 84 | 256 | 169 | 341 | 255 | 427 | 340 | 512 | 426 | 258 | 172 | |||||

| K11 | 238 | 143 | 324 | 229 | 409 | 314 | 495 | 400 | 284 | 189 | |||||||

| K12 | 221 | 118 | 307 | 203 | 392 | 289 | 478 | 374 | 310 | 206 | |||||||

| ASR-160 | K5 | 193 | 124 | 259 | 191 | 392 | 324 | 208 | 140 | ||||||||

| K6 | 165 | 83 | 232 | 149 | 365 | 282 | 498 | 415 | 250 | 168 | |||||||

| K7 | 137 | 41 | 203 | 107 | 336 | 240 | 469 | 373 | 292 | 196 | |||||||

| K8 | 176 | 66 | 309 | 199 | 442 | 237 | 575 | 465 | 708 | 598 | 333 | 223 | |||||

| K9 | 280 | 157 | 413 | 290 | 546 | 423 | 679 | 556 | 375 | 251 | |||||||

| K10 | 253 | 115 | 386 | 248 | 519 | 381 | 652 | 514 | 785 | 647 | 417 | 279 | |||||

| K11 | 358 | 207 | 491 | 340 | 624 | 473 | 757 | 606 | 458 | 307 | |||||||

| K12 | 330 | 165 | 463 | 298 | 596 | 431 | 729 | 564 | 500 | 335 | |||||||

| ASR-190 | K5 | 332 | 222 | 438 | 329 | 651 | 542 | 309 | 200 | ||||||||

| K6 | 292 | 161 | 398 | 267 | 611 | 480 | 824 | 693 | 371 | 240 | |||||||

| K7 | 252 | 99 | 358 | 205 | 571 | 418 | 784 | 631 | 433 | 280 | |||||||

| K8 | 318 | 143 | 531 | 356 | 744 | 569 | 957 | 782 | 1169 | 995 | 495 | 320 | |||||

| K9 | 491 | 295 | 704 | 507 | 917 | 720 | 1130 | 933 | 557 | 360 | |||||||

| K10 | 451 | 233 | 664 | 446 | 877 | 658 | 1090 | 871 | 1302 | 1084 | 618 | 400 | |||||

| K11 | 624 | 384 | 837 | 597 | 1050 | 809 | 1263 | 1022 | 680 | 440 | |||||||

| K12 | 584 | 322 | 797 | 535 | 1010 | 748 | 1223 | 960 | 742 | 480 | |||||||

| ASR-210 | K5 | 390 | 285 | 523 | 418 | 789 | 684 | 380 | 275 | ||||||||

| K6 | 335 | 209 | 468 | 342 | 734 | 608 | 1000 | 874 | 456 | 330 | |||||||

| K7 | 280 | 133 | 413 | 266 | 679 | 532 | 945 | 798 | 532 | 385 | |||||||

| K8 | 358 | 190 | 624 | 456 | 890 | 722 | 1156 | 988 | 1422 | 1254 | 608 | 440 | |||||

| K9 | 569 | 380 | 835 | 646 | 1101 | 912 | 1367 | 1178 | 684 | 495 | |||||||

| K10 | 514 | 304 | 780 | 570 | 1046 | 836 | 1312 | 1102 | 1578 | 1368 | 760 | 550 | |||||

| K11 | 725 | 494 | 991 | 760 | 1257 | 1026 | 1523 | 1292 | 836 | 605 | |||||||

| K12 | 670 | 418 | 936 | 684 | 1202 | 950 | 1468 | 1216 | 912 | 660 | |||||||